Concrete pump pipeline is one of the most important components in concrete pump equipment. It is the last key link in the concrete conveying of various line pump machinery. The name concrete line pump is also from its pipeline conveying method.

What Is Concrete Pump Pipe Used For?

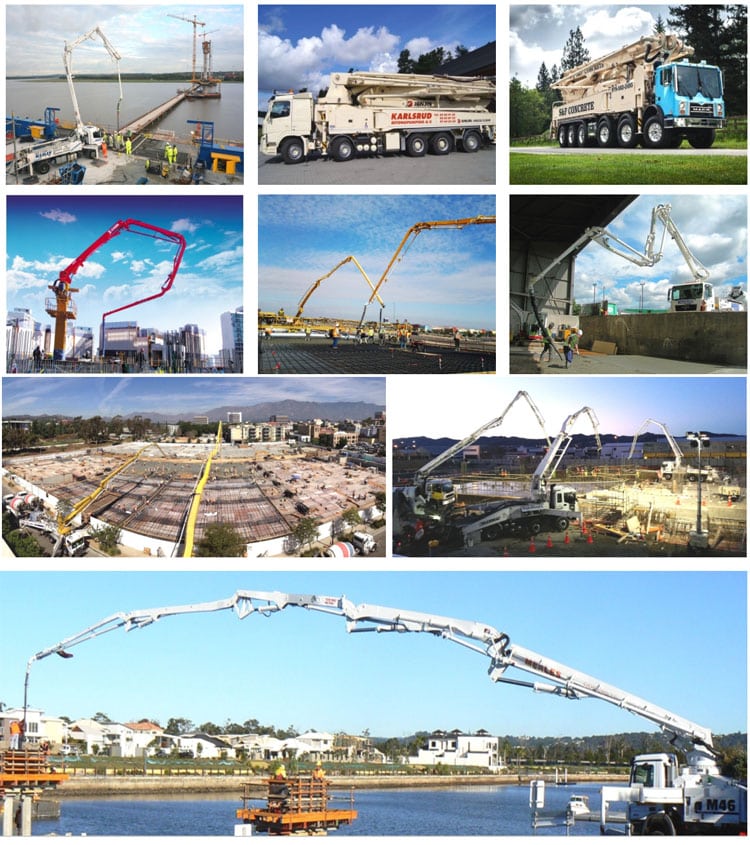

As we all know, concrete pipe is used for conveying concrete mixture to different construction areas.

Because of concrete pump pipe, concrete pumps can deliver different kinds of concrete materials to almost any construction site on any terrain. No matter at narrow tunnels, ditches, mountains, embankement dam with rugged terrain, or large scale airports, railway station constructions, concrete pipes can always guide concrete raw materials into almoste every application area.

Through resonable and flexible pipeline layout, the project construction group can greatly improve the construction efficiency and quality, therefore create more benefits.

How Many Types Of Concrete Pump Pipeline?

Concrete pump pipelines vary with different classification methods.

Use Occasions

Concrete trailer pump pipeline, concrete pump truck pipeline and fine stone pump pipeline are from different usage on various pumping machines.

Pipe Shapes

Straight pipe and elbow pipe are for different shape needed onsite.

Pipe Materials

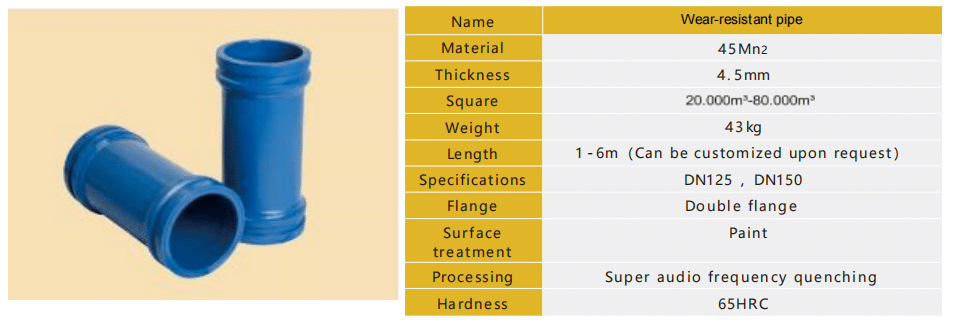

There are also different materials to made of concrete pump pipeline: steel pipe, rubber hose, plastic pipe and so on. At present, the most widely used concrete pump conveying pipeline is usually made of high strength steel material. This kind of material features as strength and durability, with high-pressure resistance, wear resistance, effectively ensuring the service life of the pipeline.

Pressurization

In order to meet different pumping pressures, the pipes are devided into high-pressure pumping pipeline and low-pressure pumping pipeline, etc.

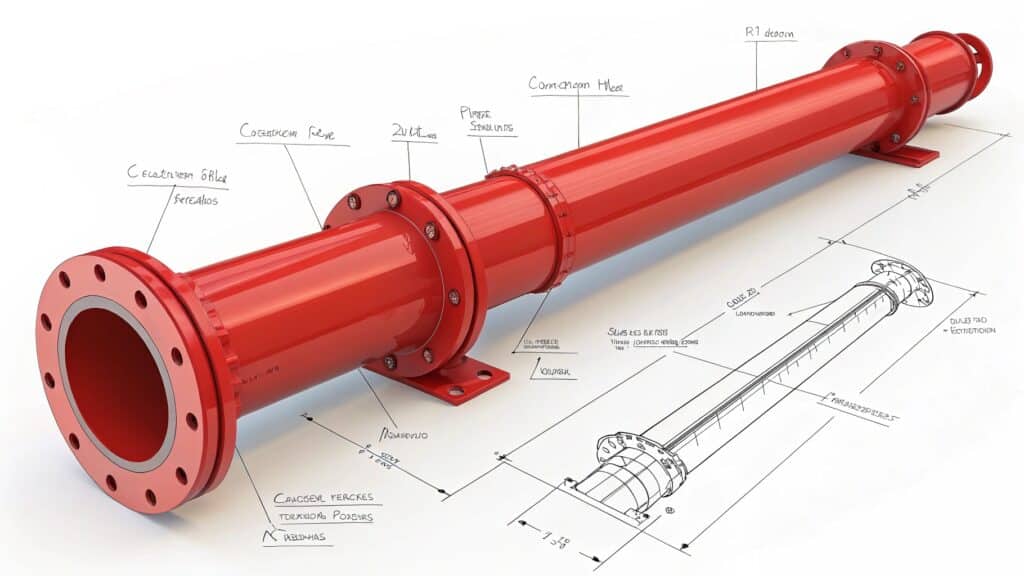

Specifications Of Concrete Pump Pipeline

Pipeline Material

The material of concrete conveying pipe mainly includs steel pipe and rubber pipe. Steel pipe is divided into ordinary steel carbon pipe and alloy steel pipe. The material of ordinary carbon steel pipe is Q235, Q345, etc. The mateial of alloy steel pipe is 16 Mn. The rubber pipe is natrual rubber or synthetic rubber material.

In the pumping process, concrete pump squeezes concrete into conveying pipelines, which requires the pipeline to have strong pressure resistance and wear resistance.

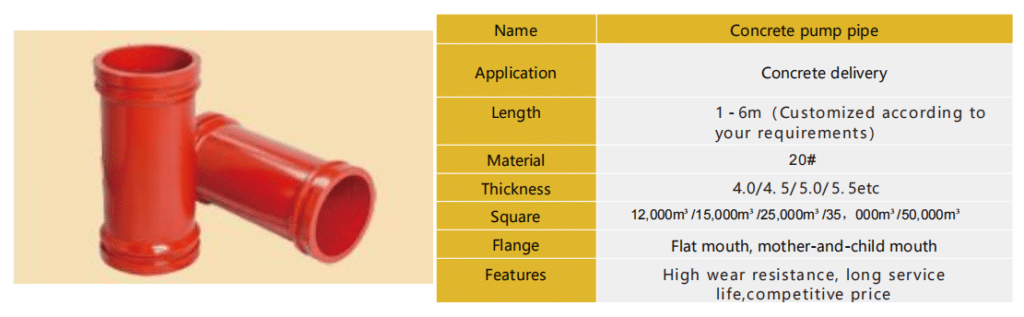

Pipeline Diameter

The pipeline diameter usually ranges from 100mm to 200mm. The most common pipe diameter for xinpeng concrete pumping pipe is 125mm. Selection of pipeline diameter depends on the viscosity of concrete and transfer distance. To ensure smooth concrete flow in pipeline, concrete with a higher viscosity or a longer delivery distance requires a larger pipe diameter.

Pipeline Length

Concrete pump pipeline is long from 1m to 6m. Xinpeng usually provides pipeline lengths including 3m, 2m, 1.5m and 1m. Generally speaking, the shorter the concrete pipeline, the more stably concrete conveys. That is because short pipeline generates less flow friction. But if the pipeline is too short, more connectors are required, which may lead to pipe leakage.

Pipe Wall Thickness

The wall thickness of concrete pump pipeline is usually between 5-7mm, so, the standard wall thickness of the pipe adopted by Xinpeng is usually 5mm. Generally speading, the thicker the pipe is, the stronger the pipe is. It means a good high-pressure resistence. But too thick pipe wall will reduce the delivery capacity of the pipe.

How To Place Concrete Pump Pipeline Onsite?

On modern construction sites, concete is delivered by various pump equipment through pre-set concrete pump pipeline. How to place concrete pump pipeline onsite is one of the most important issue of concrete conveying scheme. There are some layout principles need to take into consideration before place concrete pipeline.

Step 1

Under the circumstance of smooth concrete puming and normal concrete transmission, shorten the pipeline length and reduce elbow pipe number as possible as you can, to reduce the transmission resistance.

Step 2

The pipeline layout is depended on the pumping pressure. Place new pipeline and high-pressure pipeline at the point with high pumping pressure. Check the pipeline timely to ensure normal working condition.

Step 3

Different pumping directions need different layout methods. When the pipe is arranged downward, the drainage valve should be set at the top; When piping up, the length of the bottom horizontal section should be not less than 1/4 of the length of the vertical pipe, and not less than Im. And the stop valve should be set in a certain position. No matter the placing direction is horizontal, upward or downward, the concrete pump pipeline should all be fixed firmly, especially the elbow connecting points. The pump pipe fixation should not have any relationship with the formwork support, and the rubber between the pump pipe and the bracket.

Step 4

The vertical pipe layout should be arranged according to the construction structure characteristics. Make full use of the column, wall, floor and vertical transportation machinery, equipment holes as the support and attachment point of the vertical pipe, gradually rise to the top, and keep the whole vertical pipe in the same straight line. At the same time, convenient disassembly, easy troubleshooting, safe and reliable attachment should be also taken into consideration.

Step 5

Reinforce properly all turns of the concrete pump pipeline, and add supports along the direction of pipe vibration. The elbow closest to the pump machine is effected by the greatest pumping force, so it should be hold tightly with a firm support to reduce vibration. 6.In summer, in order to reduce the temperature of concrete into the mold, the horizontal pipe in the open air should be wrapped and watered to prevent too fast slump loss of concrete at high temperature and cause pipe blockage.